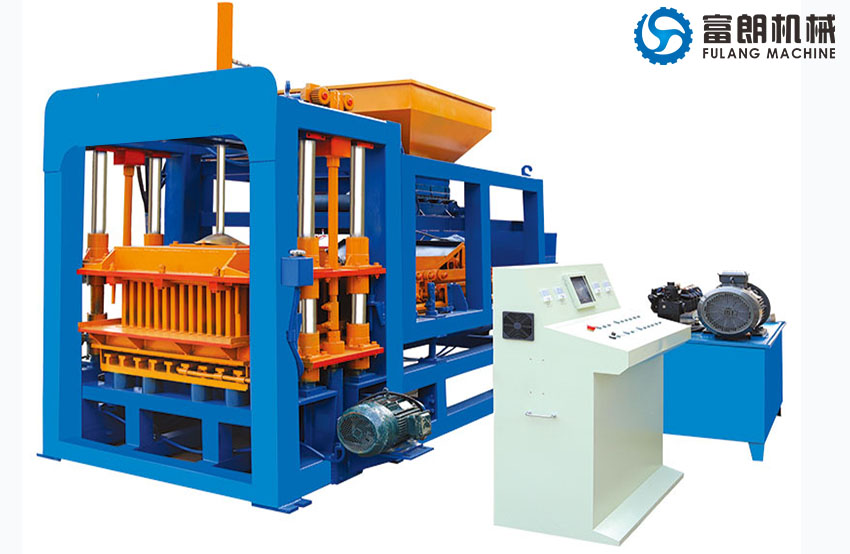

Description

Main technical advantages of QTF4-15 concrete block making machine

♦ 1. Make full use of advanced electronic control technology and reliable hydraulic system to collect the electric and hydraulic pressure in one, and realize the fully automatic PLC control, easy operation.

♦ 2. The oil consumption volume is adjusted by the imported unique proportional valves, to realize the precisely control of all actions from all direction, and make the operation more reliable and sensitive.

♦ 3. Perfect hydraulic motor make the machine have higher pressure and vibration force, but with low noise. The blocks produced have higher density and strength.

♦ 4. This block machine can use wide range of raw material, besides cement and sand, also fly ash, cinder, construction waste and some household waste.

♦ 5. The mould is replaceable to produce different kinds of hollow block, pavers and curbstone.

Technical parameters

| Dimension |

4000x1800x2800mm |

Weight |

5.51Ton |

| Shaping cycle | 15~20s | Vibration foce | 40~50KN |

| Host machine power | 21.8KW | Mixer model | JS500 |

| Pallet size | 1010x550x30mm | Certification | CE&ISO |

Production requirement

| Total area | 2600~3300m2 | Workers needed |

4~6 persons |

| Workshop | 100m2 | Distribution power | 50KW |

| Raw material store workshop | 400m2 | Water consumption | 6Ton/day |

| Office area | 60m2 | Pallet quantity | 1500 |

Installation service