Description

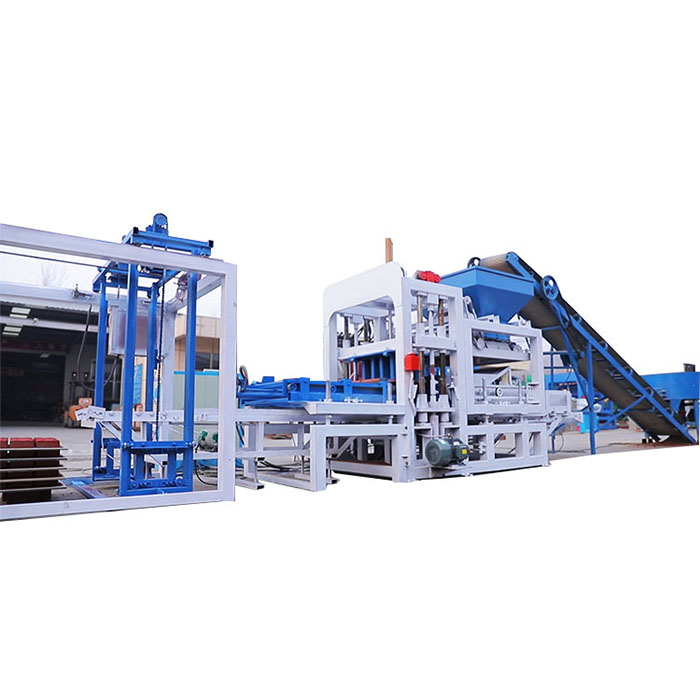

FULANG automatic brick making machine, such as QTF10-15F, QTF4-15F QTF6-15F, can produce different types of insulation brick. So what is insulation brick? Why are insulation bricks so popular?

The composite self insulation block is aimed at the development of the new wall material industry. The high-performance concrete hollow block is used as the shell, and the lightweight insulation materials, such as foam concrete or EPS board, are filled in the cavity. The concrete blocks, which are integrated with building envelope and insulation function, are formed through the production process, which makes the block shell and the insulation material integrated into a whole. Heat, sound absorption and sound insulation, simple construction, low cost, excellent comprehensive performance.

Self insulation block is made up of three parts: one is high-performance concrete hollow shell, the size is 300 ~ 400mm * 200 ~ 300mm * 190 ~ 250mm (long * width * height); the other is inorganic foam concrete insulation material, which plays the role of thermal insulation, sound absorption, sound insulation and fire resistance; there are also some EPS plates, which mainly reduce self weight, heat preservation and heat insulation; foam concrete and EPS The slab is organically combined with the concrete shell through the interface bonding technology to form a whole. The shape of self insulation block is simple, and it is easy to process and produce. The notch design at the end of the block can effectively block the thermal bridge and increase the thermal performance of the block material.