Description

►Brief introduction

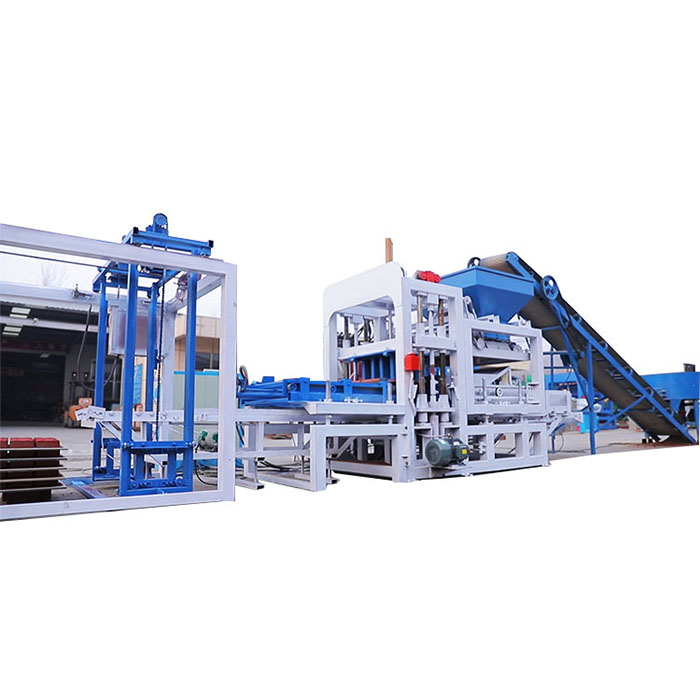

QTF6-15 automatic concrete block making machine is improved on the basis of old fly ash brick making machine QTF6-20,adopts optimized design,reasonable structure,forced material feeding and pressure acceleration vibration.It is one set of efficiency, economy brick making machine.

♦1. PLC programming control, full production automation, but can also be manual controlled, the operation is simple and efficient.

♦2. Using four-bar-oriented method and ultra-long-oriented bearing,precise movement of the mould and press head could be guaranteed.

♦3. This hollow blocks making business machine body adopts pecial welding technology and super steel,stable and durable.

♦1. PLC programming control, full production automation, but can also be manual controlled, the operation is simple and efficient.

♦2. Using four-bar-oriented method and ultra-long-oriented bearing,precise movement of the mould and press head could be guaranteed.

♦3. This hollow blocks making business machine body adopts pecial welding technology and super steel,stable and durable.

♦4. Using imported computer, electrical appliances, seals and hydraulic components,the comprehensive performance of the equipment is stable and reliable.

♦5.Double head pressed, strong vibration, especially suitable for the production of high strength block up to 20MPa.

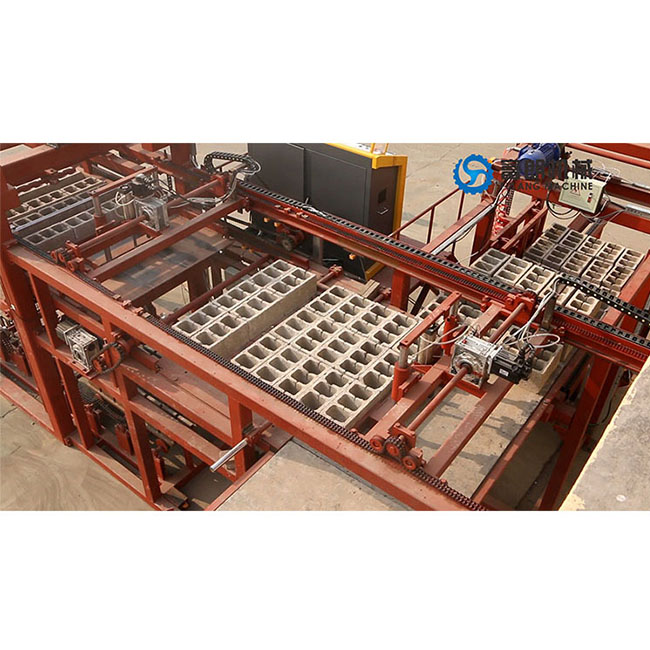

QTF6-15 automatic concrete block making machine can produce various hollow blocks,solid blocks,curbstones and pavers by changing moulds.The following bricks are some common brick types.Also we can customize brick moulds for you based on your requirements.

►Host machine main technology parameter♦5.Double head pressed, strong vibration, especially suitable for the production of high strength block up to 20MPa.

QTF6-15 automatic concrete block making machine can produce various hollow blocks,solid blocks,curbstones and pavers by changing moulds.The following bricks are some common brick types.Also we can customize brick moulds for you based on your requirements.

| Dimension |

3500x1700x2930mm |

Weight |

8Ton |

| Shaping cycle | 15~20s | Vibration foce | 50~60KN |

| Host machine power | 29.1KW | Mixer model | JS500 |

| Pallet size | 830x940x30mm | Certification | CE&ISO |

►Production requirement

| Area | 4000~6000m2 | Worker |

4~6 person |

| Workshop | 100m2 | Distribution power | 80KW |

| Raw material store workshop | 600m2 | Water consumption | 8Ton/day |

| Office | 60m2 | Pallet quantity | 1500 |