Description

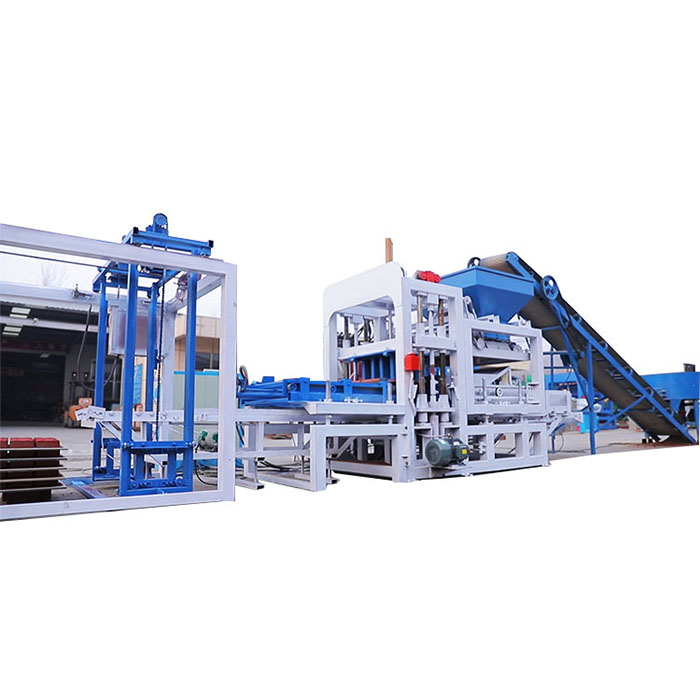

►Full line main components:

1. Host machine 2. PLC control 3. Hydraulic station 4. JS750 mixing concrete mixer 5. PLD1200 batching plant 6. Automatic stacker

7. Color material feeding machine

►Brief introduction

►Production requirement

►Our customers

1. Host machine 2. PLC control 3. Hydraulic station 4. JS750 mixing concrete mixer 5. PLD1200 batching plant 6. Automatic stacker

7. Color material feeding machine

►Brief introduction

QTF10-15 fully automatic brick making machine has reasonable design,compact structure,the body is balanced and reliable.With high efficiency, strong vibration system design, greatly improving the product's density and production efficiency.This concrete brick making machine adopts PLC control system,so the machine is in the best working condition.

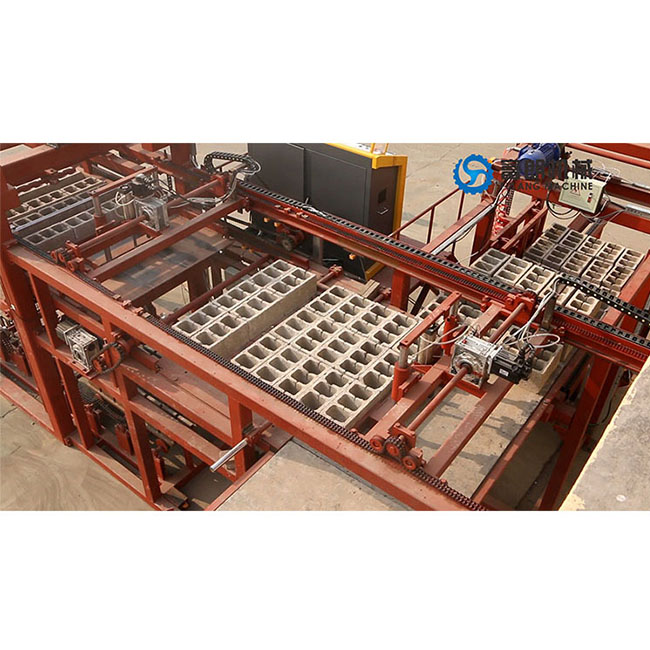

This concrtee block production line is equipped with a hydraulic stacking machine to save labor and achieve high capacity.

1. The electrical system uses the programmable controller PLC to control data input and output device, the control system includes the security logic control and fault diagnosis system.

2. Imported computer and electronic seals, hydraulic components with high dynamic performance proportional valve, in order to accurately control the action of the key parts.

3. The body of this automatic brick making machine uses high precision, high strength steel parts and special welding technology and materials to gain good rigidity, vibration resistance and long life.

4. The machine adopts the four bar guide way to ensure the accurate movement of the press head and mould.

5. Using table & mould vibration and hydraulic press forming, round-trip oriented feeding device, to achieve short shaping cycle and high production efficiency.Block produced by this concrete brick making machine are of high indensity and precise size.

6. By mechanic,electricity, liquid integration technology,the operation process of this machine stays the same, thus forming products with high stability, low reject rate.

7. Multi functional use,capable of making hollow block,solid block,paver,curb stone,porous block,grass planting brick and other cement blocks.

8. Programming according to the production needs,to fullfill manual,semi-automatic,automatic and other action.

QTF10-15 brick making machine price is very reasonable,and we can provide all the information you need to start one big block factory.

►Host machine main technology parameterThis concrtee block production line is equipped with a hydraulic stacking machine to save labor and achieve high capacity.

1. The electrical system uses the programmable controller PLC to control data input and output device, the control system includes the security logic control and fault diagnosis system.

2. Imported computer and electronic seals, hydraulic components with high dynamic performance proportional valve, in order to accurately control the action of the key parts.

3. The body of this automatic brick making machine uses high precision, high strength steel parts and special welding technology and materials to gain good rigidity, vibration resistance and long life.

4. The machine adopts the four bar guide way to ensure the accurate movement of the press head and mould.

5. Using table & mould vibration and hydraulic press forming, round-trip oriented feeding device, to achieve short shaping cycle and high production efficiency.Block produced by this concrete brick making machine are of high indensity and precise size.

6. By mechanic,electricity, liquid integration technology,the operation process of this machine stays the same, thus forming products with high stability, low reject rate.

7. Multi functional use,capable of making hollow block,solid block,paver,curb stone,porous block,grass planting brick and other cement blocks.

8. Programming according to the production needs,to fullfill manual,semi-automatic,automatic and other action.

QTF10-15 brick making machine price is very reasonable,and we can provide all the information you need to start one big block factory.

| Dimension |

3500x2300x2930mm |

Weight |

9.8Ton |

| Shaping cycle | 15~20s | Vibration foce | 100KN |

| Host machine power | 37KW | Mixer model | JS750 |

| Pallet size | 1300x900x30mm | Certification | CE&ISO |

►Production requirement

| Area | 5000~6000m2 | Worker |

4~6 person |

| Workshop | 200m2 | Distribution power | 100KW |

| Raw material store workshop | 700m2 | Water consumption | 12Ton/day |

| Office | 60m2 | Pallet quantity | 2000 |

►Our customers