Description

Brief introduction of this brick machine

FL7-10 is a fully automatic compressed earth brick making machine, and it has the following advantages:

♦1. Advanced molding technology

The vertical directional hydraulic high pressure molding technology are adopted by this machine, to make sure the excitation are concentrated on the mold, which not only increases the compactness of brick, but also reduces the noise of the frame.

♦ 2. Short molding cycle

This machine’s molding cycle is only 8-10s, and pressurized molding and finished products release are simultaneous, so the machine has very high production efficiency.

♦ 3. Upgrade of performance

The machine FL7-10 is the upgrade version of FL5-10, the machine performance and output are both improved.

♦ 4. Precise mold

Accurate line cutting technology are adopted in the process of mold production. Only by using high precise mold, the machine can produce high precise bricks, so the mold is the key components that cannot be ignored.

Technical parameters

Production line

This machine is composed of soil crusher, soil screen, JQ500 mixer, conveyor belt, host machine.

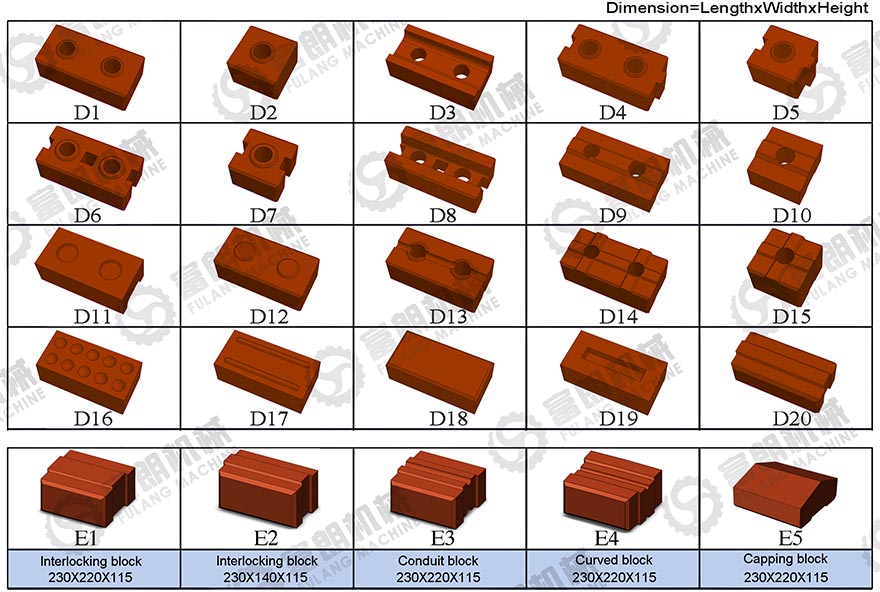

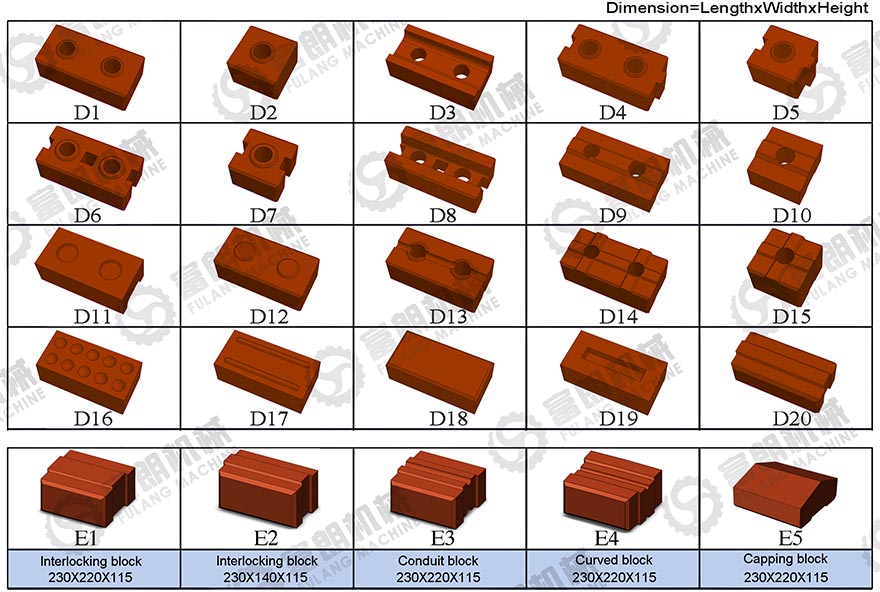

Block samples

This machine can not only produce different shapes of solid bricks, but also can produce different hole bricks and U shape bricks, just by changing mold.

| Control system |

PLC |

Weight of the host machine |

1.75Ton |

| Shaping cycle | 7-10s | Pressure | 80Mpa |

| Host machine power | 11KW | Mixer model | JQ500 |

| Production capacity | 16800pieces/8H | Workers needed | 4-6 person |

| Certificate | CE&ISO | Molding area | 1016*600mm |

Production line

This machine is composed of soil crusher, soil screen, JQ500 mixer, conveyor belt, host machine.

Block samples

This machine can not only produce different shapes of solid bricks, but also can produce different hole bricks and U shape bricks, just by changing mold.