Description

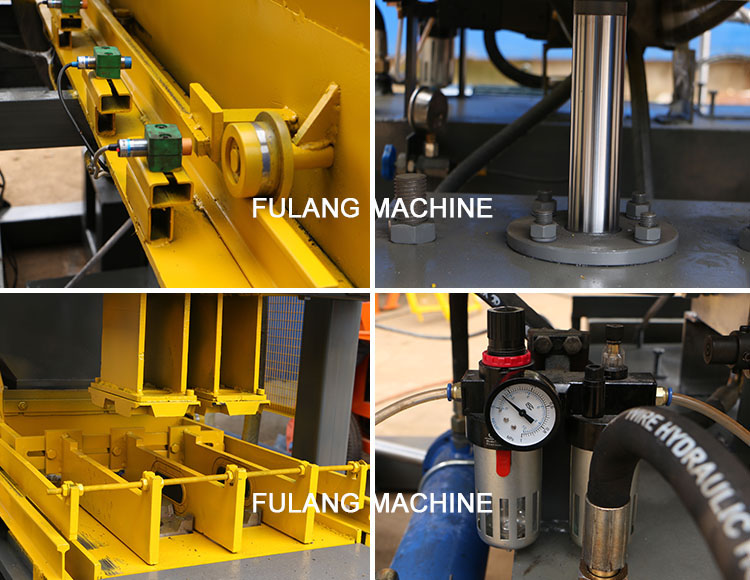

1. This interlocking brick making machine can produce 2 pieces block at one time,and the shaping cycle is only 10 seconds.Using hydraulic technology,so the blocks produced are of good quality, large density and high strength.

2. All mould use precise line cutting and carburizing treatment to prolong its service life. The machine frame is welded by special thick steel rectangle welding techniques, thus it is strong,durable and can resist vibration.

3. The fully automatic brick making machine can produce all kinds of interlocking blocks,just by changing the moulds.

4. FL2-10 compressed earth brick making machine is a small type block machine,which can be easily operated by only one person.And it has been widely used in african countries.

| Dimension |

2200*1050*2200mm | Weight |

1300Kg |

| Shaping cycle | 14-15s | Pressure |

20 tons |

| Host machine power | 11KW | Mixer model | JQ350 |

| Capacity |

4000Pcs/8 hours | Maximum block size | 300x150x100mm |

| Pieces/Mould | 2 | Voltage | Adopts to local voltage |

►Production requirement

| Area | 1600m2 | Worker |

4~5 person |

| Workshop | 100m2 | Distribution power | Three phrase power |

| Raw material store workshop | 400m2 | Water consumption | 4Ton/day |

| Office | 60m2 | Curing area | 1000m2 |

Till now,about 1200 customers have visited our factory.Also we have engineers staying abroad to help you install machines and training your workers at your side.