Description

►Brief introduction

1. The FL10-15 mobile hollow block making machine uses hydraulic technology to produce blocks of good quality, high density and high strength.

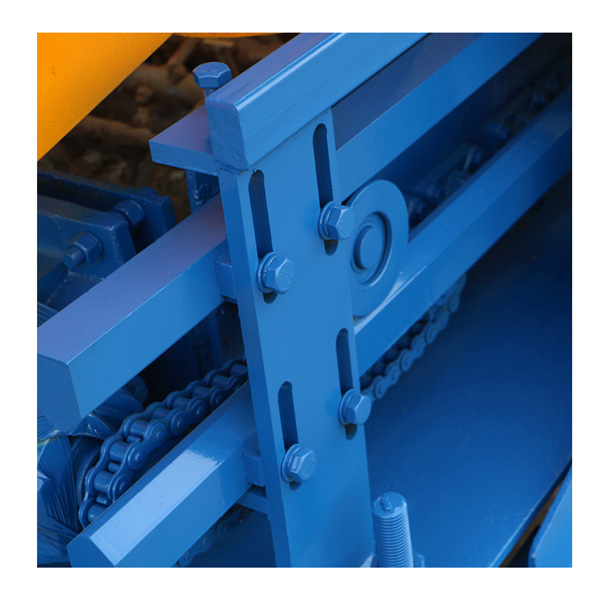

2. All concrete block moulds are precision wire cut and carburized to extend their service life.

3. The frame is welded with Q345 high performance steel. It has the advantages of high toughness, wear resistance and high strength.

4 The machine uses Siemens motors to ensure stable and efficient operation of the block machine.

5. The automatic block making machine can produce all kinds of solid bricks and hollow blocks by simply changing the mold.

| Dimension |

3150x1800x2400mm |

Weight |

4.2Ton |

| Shaping cycle | 10~15s | Vibration foce | 50KN |

| Host machine power | 18.6KW | Mixer model | JZC500 |

| Pallet size | no need pallet | Rated pressure | 16~25Mpa |

►Production requirement

| Area | 3000m2 | Worker |

3~4 person |

| Concrete ground |

2000m2 | Distribution power | 50KW |

| Raw material store workshop | 600m2 | Water consumption | 10Ton/day |

| Office | 60m2 | Pallet quantity | 0 |

►Block samples

FL10-15 concrete block making machine can produce various hollow bricks, solid bricks and curbstone by changing moulds. The following bricks are some common brick types. Also we can customize brick moulds for you on base of your specific requirements.

►Our factory

►Our factory