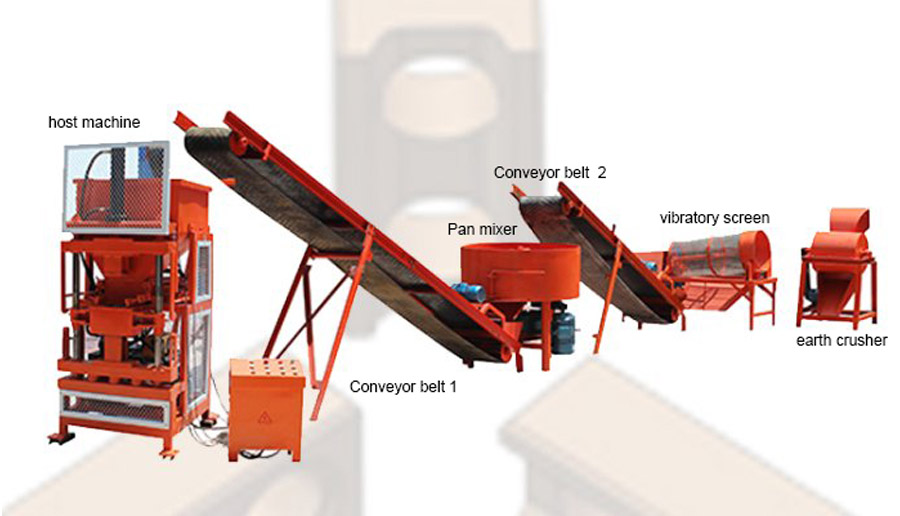

Description

FL1-10 automatic interlocking block machine produces environmentally friendly clay brick,and the shape is special designed to lock with each other,so the building process is easy to master.

♦ 1. Hydraulic pressure as high as 19Mpa and double head press makes the brick has large and even density,high strength and quality.

♦ 2. Mould adopts wire cutting and carburizing heat treatment,so it is strong and durable.

♦3. The machine frame is welded by special thick steel rectangle welding techniques,has a much longer service life.

♦ 4. By exchaning the mould easily,FL1-10 earth brick machine could make all kinds of interlocking bricks.

♦ 5. PLC control,automatic feeding,automatic scraping,automatic brick lifting,highly improve production efficiency,save lots of labor cost.

♦ 6. Adjust the screw,the brick height can be changed,it only takes 10 seconds to shape one brick.

►Host machine main technology parameter♦ 1. Hydraulic pressure as high as 19Mpa and double head press makes the brick has large and even density,high strength and quality.

♦ 2. Mould adopts wire cutting and carburizing heat treatment,so it is strong and durable.

♦3. The machine frame is welded by special thick steel rectangle welding techniques,has a much longer service life.

♦ 4. By exchaning the mould easily,FL1-10 earth brick machine could make all kinds of interlocking bricks.

♦ 5. PLC control,automatic feeding,automatic scraping,automatic brick lifting,highly improve production efficiency,save lots of labor cost.

♦ 6. Adjust the screw,the brick height can be changed,it only takes 10 seconds to shape one brick.

| Dimension |

1500x1150x2100mm |

Weight |

800Kg |

| Shaping cycle | 9s | Pressure |

18Mpa |

| Host machine power | 5.5KW | Mixer model | JQ350 |

| Capacity |

3200Pcs/8 hours | Maximum block size | 300x150x100mm |

| Pieces/Mould | 1 | Voltage | Adopts to local voltage |

►Production requirement

| Area | 1000m2 | Worker |

3~4 person |

| Workshop | 100m2 | Distribution power | 26KW |

| Raw material store workshop | 300m2 | Water consumption | 2Ton/day |

| Office | 30m2 | Curing area | 500m2 |

►Our customer

With 14 years development ,our products have been sold to more than 80 countries.Till now,about 1200 customers have visited our factory.Also we have engineers stay abroad to help you install the machines and training your workers at your side.

Previous : 100 tons pressure brick machine